Sulfur Burning

Facilities that spray molten or spent sulfuric acid rely on spray technology from Spraying Systems Co. for effective, efficient processing. Our experts will help you select the right nozzles and guns for your industry and specific needs.

Failing to achieve the proper sulfur droplet size and maintaining the proper temperature can cause problems that reduce production and decrease furnace efficiency:

- Vaporization and combustion can be compromised

- Build-up and damage to equipment can occur.

- Guns can plug, dramatically increasing maintenance time

Advanced spray technology enables us to improve your operating efficiency:

- Through decades of research and testing, we’ve compiled unmatched droplet size data

- Our computational modeling services can validate sulfur gun performance to solve problems like carryover and wall wetting – prior to purchase.

- We offer a wide range of hydraulic and air atomizing guns for spraying both molten sulfur and spent acid.

- We’ve got a proven track record of success.

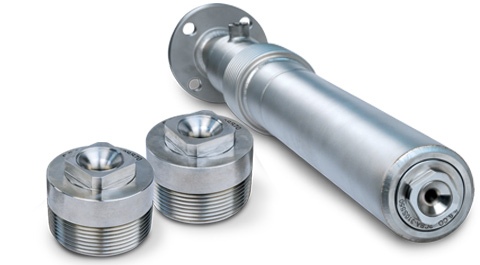

BA WhirlJet® Sulfur Guns

BA WhirlJet® Sulfur Guns, the industry standard for decades, produce the exact droplet size and droplet size distribution required for complete vaporization and efficient combustion – day in and day out. Similar looking competitive guns are available, but they fail to match the tight droplet size control and performance consistency of the BA WhirlJet guns.

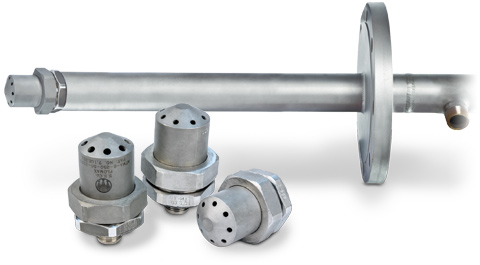

CBA WhirlJet Sulfur Guns

NEW! CBA WhirlJet Sulfur Guns offer precise performance with reduced plugging. A unique design keeps the temperature of the sulfur consistent as it passes through the gun -- even when flow rates change. This eliminates nozzle plugging caused when the temperature of the sulfur falls outside of the optimal range.

FloMax® Two-Fluid Sulfur Guns

FloMax® Two-Fluid Sulfur Guns are ideal for use in spent acid plants. FloMax guns produce uniformly small droplets that provide better decomposition and reduced risk of carryover. A unique three-stage atomization process produces a D32 droplet size 34% smaller than other two-fluid guns, using 20% less air.

Additional Spray Technology for Sulfuric Acid Production:

- Uniform Distribution (UD) FullJet® Nozzles for fume scrubbing

- PTFE SpiralJet® Full Cone Nozzles for entrainment scrubbers

- FlatJet® Nozzles for filter cloth cleaning

Contact your local rep for more information.