Hydrotreater

1. Water Wash

Problem: Inadequate chloride scrubbing, wall wetting and maldistribution of the wash water through the piping system and REAC inlets.

Best practice: Use FloMax® H two-fluid spray nozzles that use a slipstream of makeup hydrogen as the secondary fluid instead of conventional nozzles or spray quills. FloMax H nozzles maximize the surface area of the injected water and enable better contact with the chlorides and more uniform distribution of the wash water.

3 options for water wash

Quill

Quills used for water wash in hydroprocessing units typically have rectangular orifices that don’t form discrete droplets. This results in minimal surface area for chloride scrubbing. In addition, the wash water isn’t distributed uniformly and salt downstream of the injection point may not be dissolved. In some cases, this maldistribution of wash water may encourage salt formation.

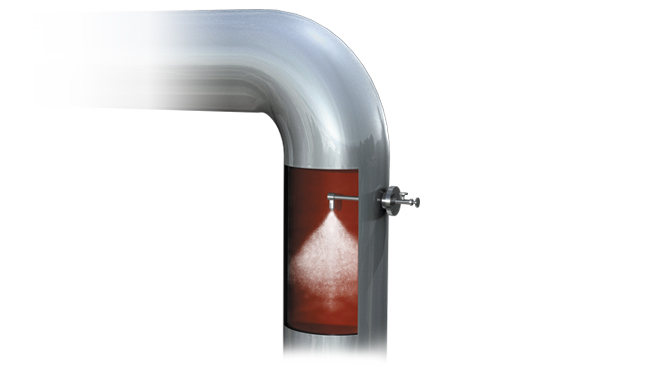

Hydraulic Spray Nozzle

Full cone and hollow cone spray nozzles form discrete droplets. However, the droplets are too large to navigate the tee and bends in piping systems installed prior to the introduction of REACs. In addition, large droplets tend to form a water film in the piping system and are susceptible to maldistribution and reduced salt dissolution.

FloMax® H

Two-fluid FloMax H spray nozzles have been engineered to optimize chloride scrubbing in water wash systems in hydroprocessing units. A slipstream of makeup hydrogen is used for atomization. The nozzle produces smaller droplets that saturate more of the vapor while maintaining 20 to 25% free water. The result is more uniform distribution of the droplets for chloride scrubbing in the piping, REAC inlets and exchanger tubes.